| #supersoaker, #DIY

DIY Super Soaker Prototype

The Super Soakers from the 1990s were engineered with clever, patented ideas advancing toy water gun technology. Since the early 2000s, toy manufacturers have abandoned these ideas and regressed to selling cheaper, simpler models that take up less shelf space and hit a lower price point. Nowadays, if you want a Super Soaker that holds up to the ones from the 90s, you have to find an old model in the used toy market or build your own. This what I have learned in building my first homemade Super Soaker.

Super Soakers had some innovative ideas

The Super Soaker was invented in 1982 by Lonnie Johnson, while he was employed by NASA’s Jet Propulsion Lab. It was ready for commercialization in 1990, first marketed as the “Power Drencher”. Dozens of variations on this design would follow.

Photos of Johnson’s prototypes and an “evolutionary tree” of the many Super Soaker models are documented in this lovingly-detailed history. A fandom Wiki enumerates the Classic (1991–1998), XP (1994–2001), and CPS (1996–2002) models.

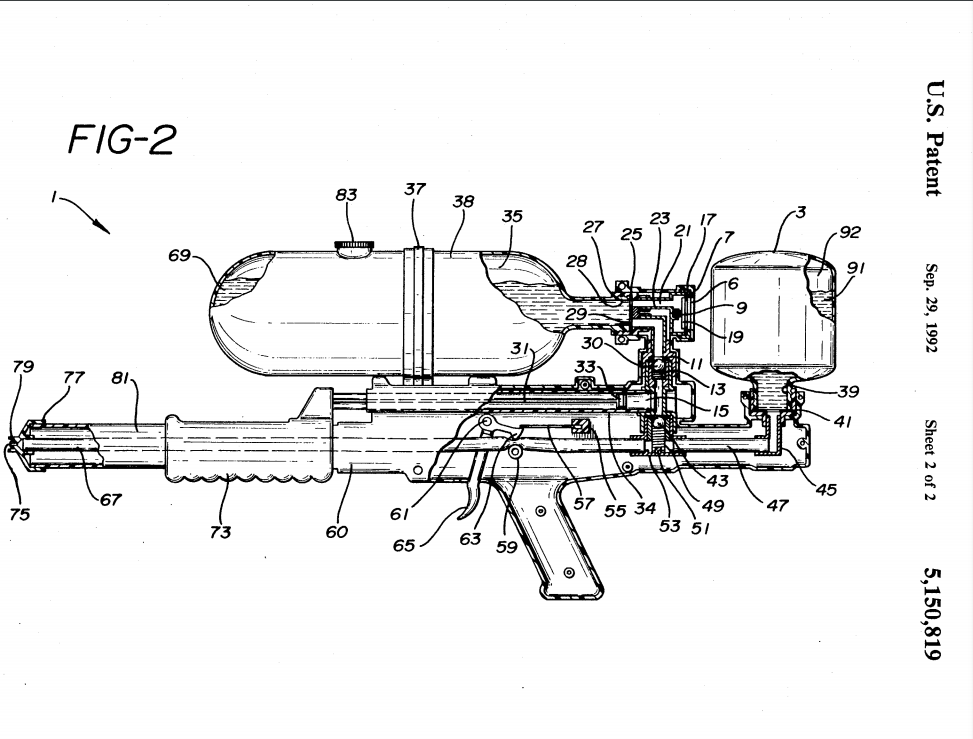

US Patent US5150819A, “Double tank pinch trigger pump water gun”, describes the innovations behind the Classic and XP models. In summary:

- Pumping the Super Soaker does not discharge it. Pressure can be stored—by means of two one-way valves—and then released via a separate trigger.

- The early Classic models have only one chamber, the water reservoir, which is

pressurized by pumping air. Later Classic and XP models have a separate charmber

for storing the pressurized air and water. This has several advantages:

- The water resevoir is now unpressurized and can be refilled during pumping or firing.

- Because the reservoir does not need to be sealed, it can be a bottle with an open hole for refilling or even a swimming pool.

- The pumping action pumps water or a mixture of water and air. This does more work per stroke than pumping air alone would do because water is incompressible.

- Finally, there is a safety trigger. To escape through the nozzle, the pressurized water and air must flow through a flexible tube. The tube is normally pinched shut by a spring. The pinched tube blocks the exit. Pressing the trigger overcomes the force the spring, allows the flexible tube to be un-pinched, and lets pressurized water spray out of the gun. This acts as a safety mechanism to ensure the Super Soaker cannot be overpressurized: at a certain maximum pressure (calibrated by the strength of that spring) the tube will open regardless of whether the trigger is pressed.

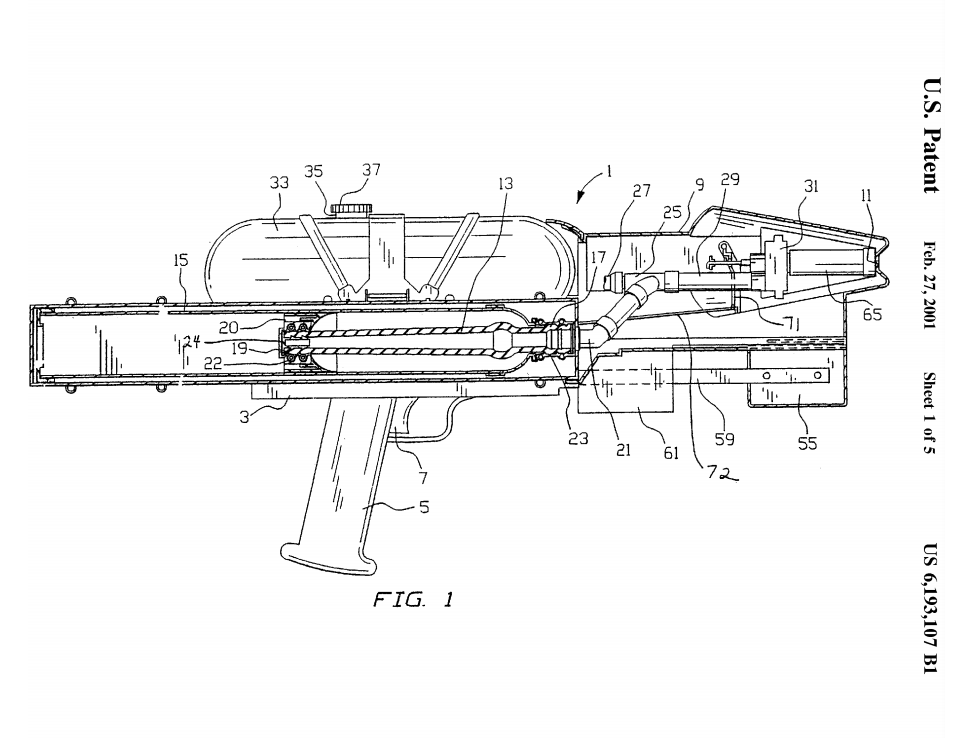

The patent is credited to Johnson and Bruce M. D’Andrade, who helped develop Johnson’s prototype into a design viable for commercial manufacture. A later patent, US6193107B1, “Bladder water gun”, credited solely to D’Andrade, describes the design underlying the CPS (Constant Pressure System) series. In a CPS model, the pumping action forces water into an elastic balloon that delivers a steady blast of water when discharged. This has some advantage over the XPs, which slow to a trickle when the pressure drops; however, it requires a lot more pumping for a comparatively short blast. CPS models also tend to be larger and heavier. The history linked above reports rumors that the CPS 2000 was removed from the market for being overpowered.

There are good D.I.Y. Super Soaker resources

In the D.I.Y. community, high-powered CPS models are popular. I am much more interested in Johnson’s original air-pressurized design. It’s more adaptable, lighter-weight, and more fun. Fortunately, there are some excellent resources on these as well. D.I.Y. implementations of Johnson’s design go by the term “Air-Pressure Homemade”. I followed a detailed guide for building one out of PVC, which was developed by Ben Trettel about a decade ago. (It made me smile to discover that Trettel is currently a PhD student studying turbulent liquid jet breakup.)

Most of the D.I.Y. resources I found, including that guide, are archives that haven’t been substantially updated since the early 2010s. I found more recent activity in the formus at WaterWar.net, where discussion consists of sharing photos of D.I.Y. builds, floating design ideas for feedback, and griping about the sorry state of commercially-available Super Soakers these days.

In 2017, D.I.Y. YouTube personality Mark Rober made a splash with a record-holding Super Soaker. His video describing the project includes an interview with Johnson.

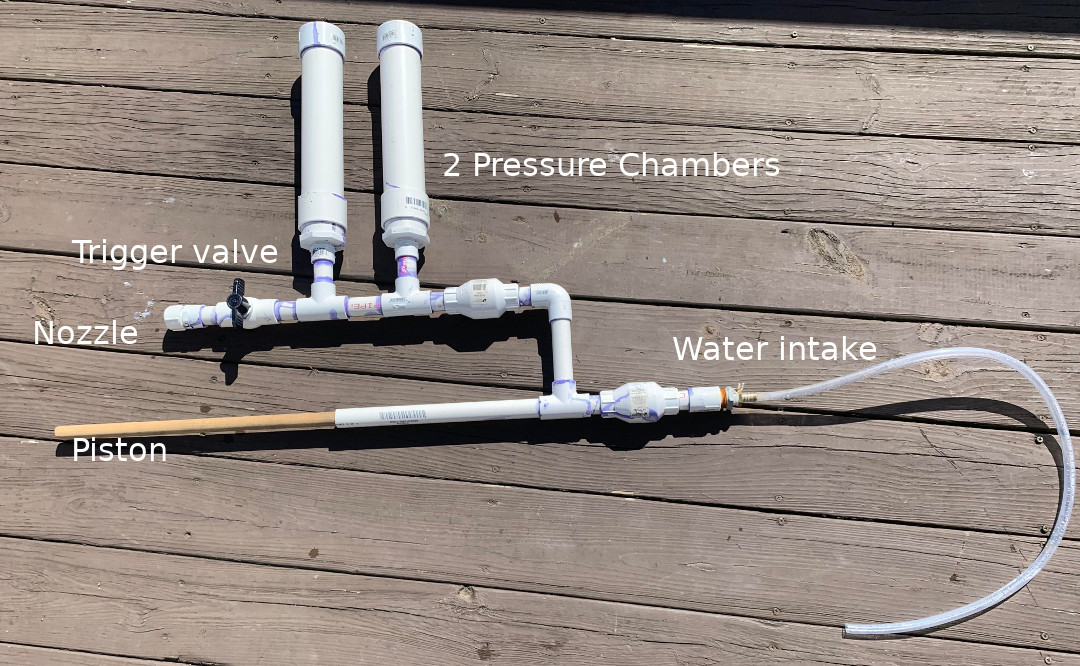

My prototype is a variation on a popular guide

My prototype follows Trettel’s guide with the following minor variations:

- The pressure chambers and the water reservoir connection are threaded on, not solvent-welded on, so I can swap out alternatives. (The nozzle is also threaded.)

- The guide uses a mixture 1/2" and 3/4" PVC. I used 3/4" throughout.

- The guide uses 3" PVC for the pressure chambers. 3" PVC was not readily available, so I made chambers of 2" PVC with equal volume. As a result, they are quite tall.

- I used mostly pressure-rated Schedule 40 PVC. Any PVC should be fine at toy-water-gun pressures, but Trettel has commented subsequently that the guide should have recommend pressure-rated PVC to be safe, and I agree. 3/4" Schedule 40 is rated up to hundreds of psi with a bursting pressure of ~1500 psi. For context, garden hose pressure is 40–70 psi, and water gun pressures are reported to be around 40 psi.

Next Steps

- My first nozzle is a sloppily-drilled 1/4" hole in PVC. A neater and smaller hole will give a more coherent stream and longer range. My prototypes has a range of about 30 feet; folks online consistently report 55–60 feet for this kind of build.

- I need a portable water reservoir—maybe a variety of them with different sizes.

- Handle-bar tape (for bicycles) can be used to make more comfortable grips.

- This was my first time solvent-welding PVC. The construction feels solid and has so far not leaked, but I could make more secure connections given a second chance. I plan to discard this as a learning experience and start from scratch. I will use exclusively Schedule 40 (pressure-rated) pipe and fixtures.

- I’d like to apply paint in the classic Super Soaker color schemes.

This shows the stream breakup and the range (about 30 feet). It will be interesting to see what difference a better nozzle will make.